Tracking Dewatering Equipment Usage in Mining Operations

Save Money and Boost Your ROI with USAT’s Wireless Solutions for MiningMine dewatering can be a critical aspect of mining operations. Mine dewatering refers to the removal of groundwater from a mine. In some cases, dewatering a mine is a minor operation that can be done as groundwater appears. But in other instances, dewatering is critical to the viability of the mine. Modern mining enterprises need dewatering pipes as essential equipment for their businesses. As do many construction enterprises, oil and gas companies, and others.

The Problem

Paying for Dewatering Pipes Only When They’re In Use

Digging in the vicinity of groundwater can be a challenge for mining companies. The dewatering pipes mentioned above are massive. Used to extract water from open-cut mine pits, most dewatering equipment is rented by the day.

However, mining companies are usually unaware of when they’ll hit groundwater in the mine. Expensive dewatering pipes are simply rented and left on-site, often sitting idle for days, or even weeks, on the chance that your mining operation will suddenly need them.

In order to help equipment renters recoup the money lost on idle dewatering pipes, USAT is able to offer a solution that enables those who provide mining customers this equipment the ability to only pay for equipment when it’s actually in use.

The Solution

Wireless AirLink RX55 Industrial Routers and Cloud Management Software

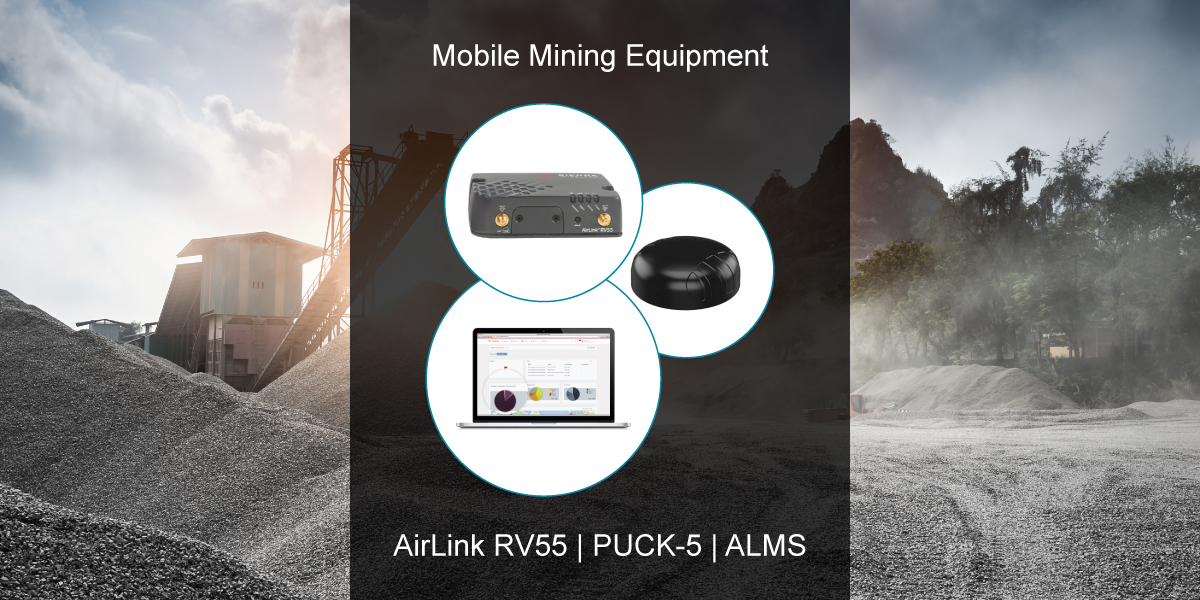

In order to accurately track the usage of equipment, we help such equipment suppliers deploy the AirLink RX55 Industrial Router. Installed in each piece of mining equipment, this solution enables the easy transfer of equipment usage data to your operations center. Instead of daily charges from critical mining equipment such as dewatering pipes, you can reduce payments to equipment rental companies with the RX55.

This benefits more than just the mining clients, as the equipment manufacturers are primarily concerned with the time their equipment is in use. Their equipment is also often used in construction environments.

The more a piece of equipment is utilized, the greater the chances of breakdowns as maintenance needs increase to ensure optimal functioning. This allows them to charge a lower rental fee per day, while charging a greater fee per minute of equipment operation. Clients only really end up paying for what they use, while the suppliers can cover the cost of equipment that can’t be rented to other clients.

The AirLink RX55 is one of the most rugged and durable wireless routers. Easy to install and manage, the RX55 was purpose-built for remote data collection for heavy-duty utility operations in hazardous environments. Built-tough to MIL-STD-810G standards, the RX55 is Class 1 Div 2 for hazardous environments with an IP64 ingress rating. When paired with Poynting’s PUCK-4 (for RX55’s without Wi-Fi) and PUCK-5 (for RX55’s with Wi-Fi) antennas affixed to each piece of equipment, reliable and rugged connectivity is achieved with high accuracy GPS.

Unlike prior generations of wireless routers from Sierra Wireless that operate using their ALEOS framework, the AirLink RX55 is powered by their newer and more robust AirLink OS that provides fast, seamless networking, with application-based configuration, and tight connection with the cloud.

Additionally, when combined with AirLink Management Service (specifically AirLink Complete) you can provision, manage, and troubleshoot all of your mining equipment. The comprehensive intelligence of AirLink OS and AirLink Complete simplifies the tracking of equipment usage, lowering your TCO.

For the organizations performing the mining operations, they can also deploy their own RX55 routers at worksites. They can pair the RX55 with our HELI-19 Tunnel Antenna from Poynting to achieve reliable Wi-Fi connectivity for workers and equipment deep inside mining tunnels and shafts.

And when those worksites are far from local cellular towers, the Poynting LPDA-92 Directional Antenna helps connect at great distances within remote environments. And for their owned and mobile mining and excavating equipment, they can install AirLink RV55 for mobile connectivity, Wi-Fi, and GPS capabilities.

The Results

Low Your TCO Through Better Equipment Monitoring

Moving from a daily rental flat fee to a more sophisticated accounting system based on usage saves money. It also enables mining companies to monitor wear and tear on their machines and equipment, allowing them to do predictive maintenance without holding up the project.

This saves much more money in the long run than manually fixing equipment after the fact and spending too much on the equipment rentals necessary for your operation.

The Team

Device Provisioning, Activation, and Installation Services

USAT has provided wireless connectivity solutions to oil, gas, and mining organizations as well as industrial automation and equipment manufacturers for over 25 years. With our catalog of the industry’s best wireless routers and gateways for continuous coverage in the most remote and inhospitable terrains, we have your networking needs covered.

Our engineering team offers professional services complete with implementation, training, proof of concept (POC), system auditing, and on-site RF surveying services with optional engineering maintenance contracts. Our team not only helps you select, provision, and activate devices, we make sure they work in practical applications and real-life situations

Enhanced connectivity at mining sites reduces your total business costs by eliminating unnecessary overhead. Contact the experts at USAT to discover how we can help your organization reach its goals.

Contact Us

Contact USAT to Engineer Your Equipment Tracking Solutions Today

Click an image below to give us a call, send us an email, fill out a contact form, or make a purchase directly on our website.

Recommended Devices for Equipment Management

Click an Image Below to Start Shopping Online

Additional Reading

Check Out Other Recent Articles, Use Cases, and Case Studies

Share this Post